Zero Waste Week is a timely reminder that the most sustainable future is one where nothing goes to waste. For Cullen, that’s not just a once-a-year ambition – it’s how we operate every single day.

As Europe’s largest manufacturer of corrugate and moulded fibre packaging, we’ve built sustainability into every step of our process. From design to delivery, our goal is simple: eliminate waste, reduce single-use plastic, and create packaging solutions that protect products, people, and the planet.

The Closed Loop in Action

At the heart of our zero waste commitment is a closed loop manufacturing process. Here’s how it works:

- Every day, we manufacture corrugated packaging for businesses across food, drink, retail, e-commerce, and industrial sectors.

- Any offcuts from that process are not discarded. Instead, they are collected, processed, and reused.

- Those offcuts become the raw material for our moulded fibre division, where they are transformed into millions of sustainable moulded fibre packaging products each week.

It’s a cycle where nothing is wasted and everything has value – proof that waste can be the starting point for innovation.

Zero Waste Packaging, Real-World Solutions

Our closed loop process supports a diverse range of packaging solutions that businesses can rely on year-round. Each product family is part of the same story: protecting goods while protecting the environment.

From vineyards and breweries to e-commerce subscription services, our drinks packaging range – including beerGUARD, Clinker, Safansound, and KEGguard ensures bottles, cans, and kegs arrive safely, without plastic and without damage. These moulded fibre solutions are not only sustainable, but also tested to perform under the pressures of modern distribution.

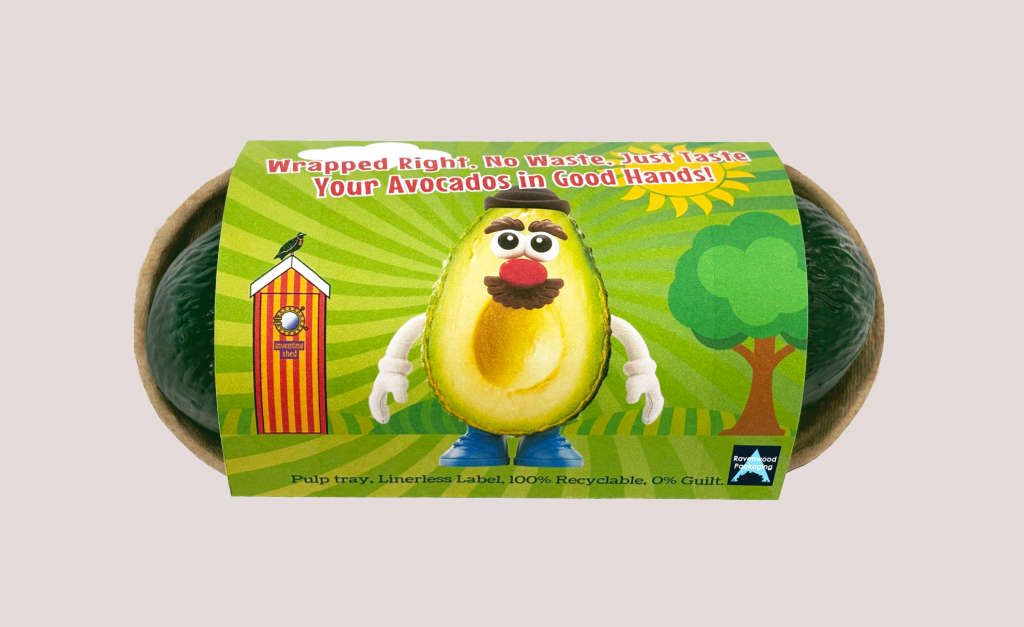

Fresh produce trays are a prime example of zero waste packaging in action. Made from recycled materials and fully recyclable after use, they’re designed to protect fruit and vegetables in transit while supporting a truly circular economy.

Our bakery carriers – from muffin to cupcake trays – combine durability with sustainability. Manufactured from recycled fibre and recyclable again after use, they keep baked goods safe in transit while reducing single-use packaging waste.

Coffee cup carriers and food-to-go packaging are everyday essentials for hospitality businesses. By choosing moulded fibre alternatives to plastic or polystyrene, our customers keep millions of single-use plastics out of circulation every year.

Our moulded fibre paint fitments provide secure, sustainable protection for tins in transit. Designed to prevent leaks and damage, they deliver strength without plastic while keeping resources in the circular economy.

From corner and channel protectors to chemical packs, our industrial solutions showcase zero waste principles in action. Made from recycled fibre and recyclable again after use, they provide robust protection without compromise.

From shelf-ready packs to e-commerce shippers, our corrugated packaging is engineered for performance. And because offcuts from corrugate production feed directly into moulded fibre manufacturing, even the waste generated during production is put back to work.

For businesses with unique needs, our in-house design team creates bespoke packaging tailored to specific products. The benefit? Tailored protection that still supports a circular economy.

Protect Every Product. Deliver Every Sale.

Packaging is more than a box or a tray – it’s the first physical touchpoint your customer has with your product. If it arrives damaged, you risk not only a return but also a loss of repeat business. That’s why we test our packaging rigorously, ensuring it offers maximum protection during transit.

By reducing the risk of product damage, you:

- Keep customers happy and increase loyalty

- Lower the cost of returns and replacements

- Protect your brand reputation during the busiest sales season

Why Zero Waste Matters

Waste is more than just an environmental issue – it’s a business challenge. Rising material costs, stricter regulations, and consumer demand for sustainable solutions all mean that eliminating waste is no longer optional.

By following a closed loop model, Cullen offers businesses:

- Sustainability at scale – millions of products manufactured weekly with zero waste.

- UK-made reliability – shorter supply chains, lower carbon impact, and secure supply.

- Plastic-free performance – protection that rivals and replaces traditional plastics.

- Future-proof packaging – solutions that align with customer and regulatory expectations.

Zero Waste Week and Beyond

Zero Waste Week is about making small changes with a big impact. At Cullen, we believe those changes should be built into everyday business operations. By closing the loop, we ensure that every offcut, every product, and every shipment contributes to a circular economy.

From a coffee cup carrier to a corrugated e-commerce shipper, every Cullen product is part of a bigger story: turning waste into opportunity and designing packaging that performs for businesses today while protecting the planet for tomorrow.

Ready to Rethink Waste?

Zero waste isn’t a challenge to face alone. With Cullen, businesses have a partner that’s already making it happen — at scale, every day.

Discover our full range of zero waste packaging solutions today.

Zero Waste Week is a timely reminder that the most sustainable future is one where nothing goes to waste. For Cullen, that’s not just a once-a-year ambition – it’s how we operate every single day.

As Europe’s largest manufacturer of corrugate and moulded fibre packaging, we’ve built sustainability into every step of our process. From design to delivery, our goal is simple: eliminate waste, reduce single-use plastic, and create packaging solutions that protect products, people, and the planet.

The Closed Loop in Action

At the heart of our zero waste commitment is a closed loop manufacturing process. Here’s how it works:

- Every day, we manufacture corrugated packaging for businesses across food, drink, retail, e-commerce, and industrial sectors.

- Any offcuts from that process are not discarded. Instead, they are collected, processed, and reused.

- Those offcuts become the raw material for our moulded fibre division, where they are transformed into millions of sustainable moulded fibre packaging products each week.

It’s a cycle where nothing is wasted and everything has value – proof that waste can be the starting point for innovation.

Zero Waste Packaging, Real-World Solutions

Our closed loop process supports a diverse range of packaging solutions that businesses can rely on year-round. Each product family is part of the same story: protecting goods while protecting the environment.

From vineyards and breweries to e-commerce subscription services, our drinks packaging range – including beerGUARD, Clinker, Safansound, and KEGguard ensures bottles, cans, and kegs arrive safely, without plastic and without damage. These moulded fibre solutions are not only sustainable, but also tested to perform under the pressures of modern distribution.

Fresh produce trays are a prime example of zero waste packaging in action. Made from recycled materials and fully recyclable after use, they’re designed to protect fruit and vegetables in transit while supporting a truly circular economy.

Our bakery carriers – from muffin to cupcake trays – combine durability with sustainability. Manufactured from recycled fibre and recyclable again after use, they keep baked goods safe in transit while reducing single-use packaging waste.

Coffee cup carriers and food-to-go packaging are everyday essentials for hospitality businesses. By choosing moulded fibre alternatives to plastic or polystyrene, our customers keep millions of single-use plastics out of circulation every year.

Our moulded fibre paint fitments provide secure, sustainable protection for tins in transit. Designed to prevent leaks and damage, they deliver strength without plastic while keeping resources in the circular economy.

From corner and channel protectors to chemical packs, our industrial solutions showcase zero waste principles in action. Made from recycled fibre and recyclable again after use, they provide robust protection without compromise.

From shelf-ready packs to e-commerce shippers, our corrugated packaging is engineered for performance. And because offcuts from corrugate production feed directly into moulded fibre manufacturing, even the waste generated during production is put back to work.

For businesses with unique needs, our in-house design team creates bespoke packaging tailored to specific products. The benefit? Tailored protection that still supports a circular economy.

Protect Every Product. Deliver Every Sale.

Packaging is more than a box or a tray – it’s the first physical touchpoint your customer has with your product. If it arrives damaged, you risk not only a return but also a loss of repeat business. That’s why we test our packaging rigorously, ensuring it offers maximum protection during transit.

By reducing the risk of product damage, you:

- Keep customers happy and increase loyalty

- Lower the cost of returns and replacements

- Protect your brand reputation during the busiest sales season

Why Zero Waste Matters

Waste is more than just an environmental issue – it’s a business challenge. Rising material costs, stricter regulations, and consumer demand for sustainable solutions all mean that eliminating waste is no longer optional.

By following a closed loop model, Cullen offers businesses:

- Sustainability at scale – millions of products manufactured weekly with zero waste.

- UK-made reliability – shorter supply chains, lower carbon impact, and secure supply.

- Plastic-free performance – protection that rivals and replaces traditional plastics.

- Future-proof packaging – solutions that align with customer and regulatory expectations.

Zero Waste Week and Beyond

Zero Waste Week is about making small changes with a big impact. At Cullen, we believe those changes should be built into everyday business operations. By closing the loop, we ensure that every offcut, every product, and every shipment contributes to a circular economy.

From a coffee cup carrier to a corrugated e-commerce shipper, every Cullen product is part of a bigger story: turning waste into opportunity and designing packaging that performs for businesses today while protecting the planet for tomorrow.

Ready to Rethink Waste?

Zero waste isn’t a challenge to face alone. With Cullen, businesses have a partner that’s already making it happen — at scale, every day.

Discover our full range of zero waste packaging solutions today.