Recycle Week 2025 is here, and this year’s theme is a simple one: taking action. At Cullen, recycling is not just a campaign or a tick-box exercise – it’s the foundation of how we design and manufacture our packaging. We don’t just talk about sustainability; we build it into every product that leaves our site.

As the UK’s only large-scale packaging manufacturer producing both corrugated cardboard and moulded fibre packaging on one site, Cullen has a unique advantage: we can recycle our own materials in-house, creating a true circular economy.

Turning Corrugate Offcuts Into Moulded Fibre

We manufacture corrugated packaging across industries. Like any manufacturing process, producing corrugate packaging generates offcuts and trimmings. In many businesses, these materials might be treated as waste.

At Cullen, we see them as raw materials for the next stage of the cycle. Instead of sending offcuts away, we process them on-site in our moulded fibre facility. Those corrugate offcuts are pulped, shaped, and transformed into strong, plastic-free moulded fibre packaging.

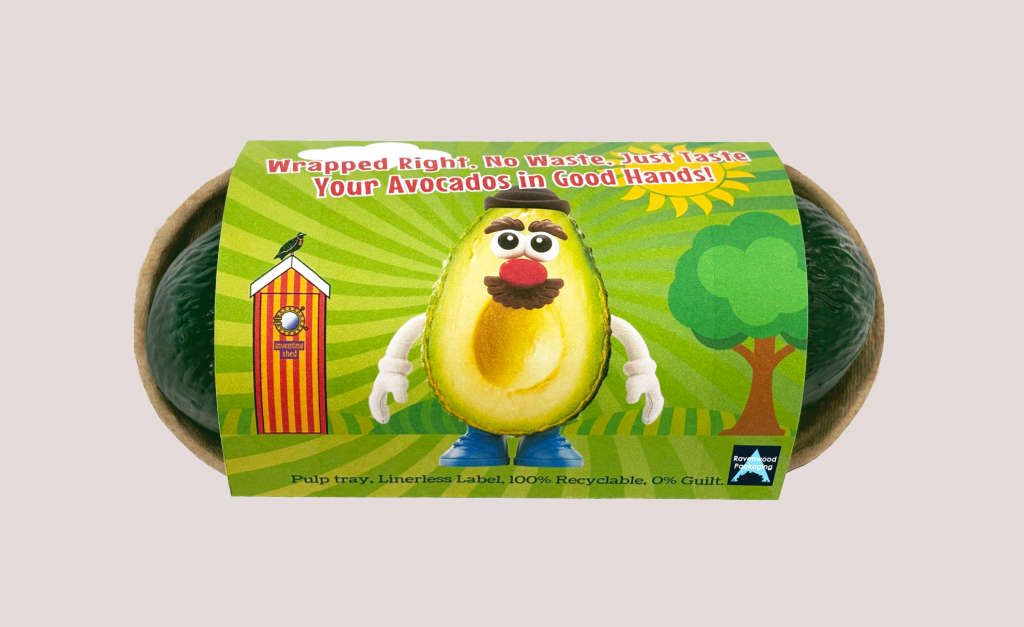

That same fibre goes on to protect millions of products every year – from produce trays that safeguard fruit and vegetables, to cup carriers that make takeaway drinks safer, to bespoke designs created to meet the unique needs of our customers.

This closed-loop system means we reduce waste, cut transport emissions, and prove that packaging really can be designed for second lives.

Industrial Recycling

It’s worth noting that Cullen’s recycling process is not the same as household recycling. We don’t recycle household materials or consumer packaging waste. Instead, we focus on recycling our own corrugate offcuts from the production line, they go straight to our moulded fibre production area to be reused .

This industrial-scale recycling ensures:

- A consistent supply of fibre for moulded fibre packaging.

- Full quality control over the materials we reuse.

- A process that delivers sustainability at scale for our customers.

By designing our manufacturing with recycling built in, we create packaging that businesses can rely on – sustainable solutions produced without compromise on performance.

A Circular Economy In Action

Our recycling approach is built on three simple principles:

- Nothing wasted: every corrugate offcut has a purpose.

- Plastic-free solutions: moulded fibre replaces single-use plastics in transit and retail packaging.

- UK manufacturing: by recycling and producing on one site in Glasgow, we cut out unnecessary transport and keep our carbon footprint low.

This isn’t recycling as an afterthought – it’s designed into the way Cullen operates. By creating both corrugate and moulded fibre packaging side by side, we ensure that resources stay in use for longer and deliver value well beyond a single application.

Why Businesses Choose Cullen’s Sustainable Packaging

Choosing sustainable packaging isn’t just about meeting recycling targets. It’s about brand trust, customer experience, and future-proofing supply chains. More than 86% of UK consumers say they want less single-use plastic in the products they buy. Retailers and producers that make the switch to recyclable, plastic-free alternatives aren’t just reducing their environmental impact – they’re meeting growing consumer demand.

Cullen helps businesses achieve this with:

- Proven performance – robust packaging designed to protect products through storage, transit, and retail.

- Scalable supply – with production of over one billion pieces of moulded fibre packaging each year, we meet demand at speed.

- Sustainable credentials – packaging designed with recycling, reuse, and waste reduction at its core.

Why Recycle Week Matters

Recycle Week is an opportunity to raise awareness, but at Cullen, recycling is not something we do once a year – it’s every week of the year. By keeping materials in circulation and giving them a second life, we’re showing how packaging can be part of the solution to global waste challenges.

Our commitment is simple: create packaging that works for our customers while working for the planet. Whether it’s corrugate, moulded fibre, or a custom solution, everything we design starts with sustainability in mind.

Made For Second Lives

This Recycle Week, we’re proud to highlight the role our packaging plays in a circular economy. By transforming corrugate offcuts into moulded fibre products, Cullen demonstrates that packaging is not just designed for today’s deliveries – it’s designed for tomorrow’s possibilities.

Because at Cullen, our products are made for second lives.