Plastic-Free Produce Packaging That Performs

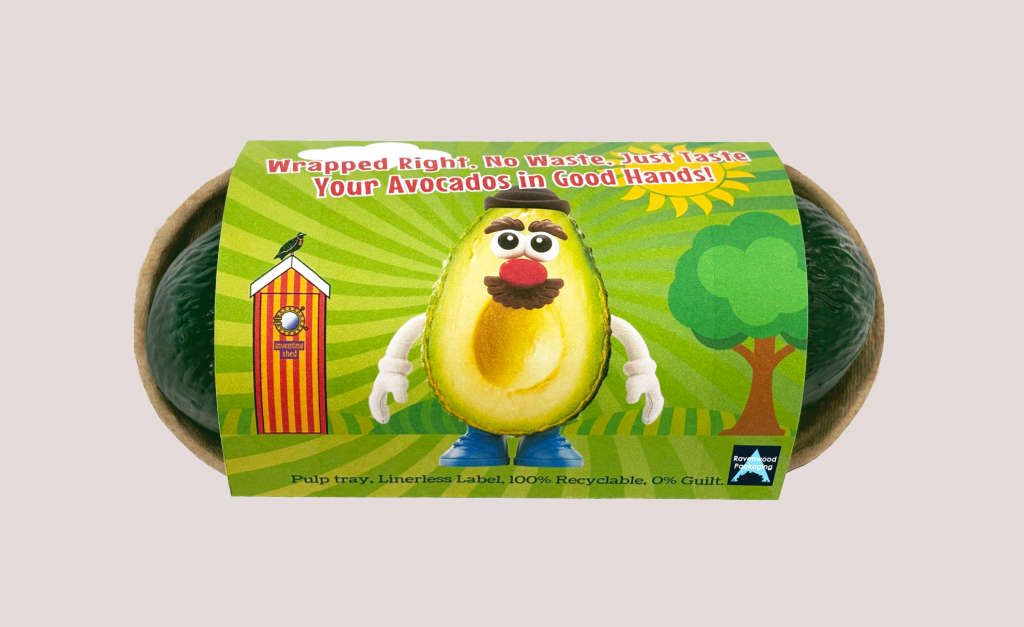

At Fruit Attraction 2025 in Madrid this September, Ravenwood Packaging will showcase its latest linerless innovation – the Nobac 5000PT – developed for applying full-wrap, linerless labels to moulded fibre trays. At the heart of this launch are trays manufactured by Cullen, the UK’s leading moulded fibre packaging producer.

A Complete Solution for Fresh Produce

The partnership between Cullen and Ravenwood means fresh produce suppliers now have a proven alternative to plastic trays – one that’s designed to work across transport, display, and labelling. Together, the trays and labels deliver:

- Plastic-free packaging – made from renewable, recyclable, and compostable materials.

- High-impact branding – linerless full-wrap labels without the liner waste.

- Strength and protection – lightweight trays that perform in demanding supply chains.

- Shelf-ready appeal – natural, breathable packaging that helps keep produce fresher for longer.

This solution gives growers, packers, and retailers confidence that their packaging not only meets today’s regulations but also strengthens sustainability credentials in the eyes of consumers.

Why Moulded Fibre Trays Are Leading the Way

Moulded fibre trays are quickly becoming the preferred choice for produce packaging, replacing traditional plastic trays. Cullen’s trays are:

- Fully recyclable and compostable – supporting retailers with current and future regulations.

- Made from renewable, recycled materials – reducing reliance on single-use plastics.

- Lightweight yet strong – offering reliable protection across the supply chain.

- Naturally breathable – helping extend produce freshness.

Already trusted by major supermarket brands, Cullen’s moulded fibre trays offer a proven, reliable, and sustainable alternative to plastic packaging. When combined with Ravenwood’s linerless wraps, they give suppliers the opportunity to reduce plastic use, strengthen sustainability credentials, and boost consumer confidence.

Cullen and Ravenwood: Collaboration in Action

The trays demonstrated at Fruit Attraction are manufactured by Cullen and supplied in partnership with Produce Packaging. This collaboration shows how innovation and partnership can accelerate the transition towards a sustainable future for fresh produce packaging.

Visit Cullen and Ravenwood at Fruit Attraction 2025

Visitors to Stand 8B28 will be able to see Cullen’s moulded fibre produce trays labelled with Ravenwood’s linerless technology in action.

At Cullen, we’re proud to see our moulded fibre produce trays at the centre of this development, helping brands reduce waste, comply with regulations, and deliver packaging solutions that consumers trust.

Count of Cullen this Christmas

Our UK-manufactured, plastic-free, recyclable packaging is designed to keep every order safe, secure, and celebration-ready. Robust moulded fibre fitments cradle each bottle or can, minimising movement during transit and ensuring it arrives in perfect condition — ready to be chilled and enjoyed.

As Gran Ethel says, “Christmas without my sherry? Unthinkable!” With Cullen, every bottle arrives intact, your customers stay smiling, and the festive spirit keeps bubbling.

The countdown to Christmas is on! Now’s the time to place your packaging order and make sure every dram, pint, and fizz arrives intact. With Cullen, families like the Grubbs — and yours — can enjoy their celebrations without a hiccup, keeping the festive spirit flowing and the day merry for everyone.

Ready to find out how Cullen can help with your packaging needs!

Plastic-Free Produce Packaging That Performs

At Fruit Attraction 2025 in Madrid this September, Ravenwood Packaging will showcase its latest linerless innovation – the Nobac 5000PT – developed for applying full-wrap, linerless labels to moulded fibre trays. At the heart of this launch are trays manufactured by Cullen, the UK’s leading moulded fibre packaging producer.

A Complete Solution for Fresh Produce

The partnership between Cullen and Ravenwood means fresh produce suppliers now have a proven alternative to plastic trays – one that’s designed to work across transport, display, and labelling. Together, the trays and labels deliver:

- Plastic-free packaging – made from renewable, recyclable, and compostable materials.

- High-impact branding – linerless full-wrap labels without the liner waste.

- Strength and protection – lightweight trays that perform in demanding supply chains.

- Shelf-ready appeal – natural, breathable packaging that helps keep produce fresher for longer.

This solution gives growers, packers, and retailers confidence that their packaging not only meets today’s regulations but also strengthens sustainability credentials in the eyes of consumers.

Why Moulded Fibre Trays Are Leading the Way

Moulded fibre trays are quickly becoming the preferred choice for produce packaging, replacing traditional plastic trays. Cullen’s trays are:

- Fully recyclable and compostable – supporting retailers with current and future regulations.

- Made from renewable, recycled materials – reducing reliance on single-use plastics.

- Lightweight yet strong – offering reliable protection across the supply chain.

- Naturally breathable – helping extend produce freshness.

Already trusted by major supermarket brands, Cullen’s moulded fibre trays offer a proven, reliable, and sustainable alternative to plastic packaging. When combined with Ravenwood’s linerless wraps, they give suppliers the opportunity to reduce plastic use, strengthen sustainability credentials, and boost consumer confidence.

Cullen and Ravenwood: Collaboration in Action

The trays demonstrated at Fruit Attraction are manufactured by Cullen and supplied in partnership with Produce Packaging. This collaboration shows how innovation and partnership can accelerate the transition towards a sustainable future for fresh produce packaging.

Visit Cullen and Ravenwood at Fruit Attraction 2025

Visitors to Stand 8B28 will be able to see Cullen’s moulded fibre produce trays labelled with Ravenwood’s linerless technology in action.

At Cullen, we’re proud to see our moulded fibre produce trays at the centre of this development, helping brands reduce waste, comply with regulations, and deliver packaging solutions that consumers trust.

Count of Cullen this Christmas

Our UK-manufactured, plastic-free, recyclable packaging is designed to keep every order safe, secure, and celebration-ready. Robust moulded fibre fitments cradle each bottle or can, minimising movement during transit and ensuring it arrives in perfect condition — ready to be chilled and enjoyed.

As Gran Ethel says, “Christmas without my sherry? Unthinkable!” With Cullen, every bottle arrives intact, your customers stay smiling, and the festive spirit keeps bubbling.

The countdown to Christmas is on! Now’s the time to place your packaging order and make sure every dram, pint, and fizz arrives intact. With Cullen, families like the Grubbs — and yours — can enjoy their celebrations without a hiccup, keeping the festive spirit flowing and the day merry for everyone.

Ready to find out how Cullen can help with your packaging needs!